Dwell Winding

Cadfil Help contents

Cadfil Help contents  Cadfil.com Home

Cadfil.com Home

On the band pattern selection dialog there are buttons to switch from progression winding to dwell winding.

Band Pattern Selection Dialogue

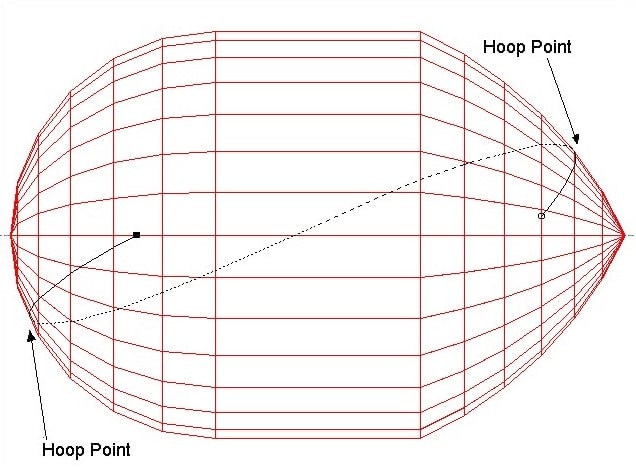

In dwell winding the modification to mandrel achieve a band pattern is achieved by additional mandrel rotation at the hoop (turning) points.

Two Hoop Points

Normally the dwell rotation is split equally (50:50) between the two turning

positions in the program. The dwell-split feature allows the dwell to be

biased between the ends 100:0 has all the dwell at the first hoop position and

0:100 has all the dwell at the second (last) hoop position. Dwell split is only

available if dwell winding is selected. Currently this feature is implemented for Cadfil Axsym, pipe winding, dome vessel and vessel with

end-caps. For other options it is ignored. The Default split value is 50:50 but this can be changed by setting the

$DWELL-SPLIT= in the SM file (

see

topic on this configuration file

). $DWELL-SPLIT takes value 0.0 to 1.0.

Dwell winding has advantages and disadvantages as follows:

Disadvantages:

It leads to an extra increase in thickness at the turning points

In general it can only be used when the hoop points are on a cylinder otherwise fibre slip will occur.

The exception is when the dome end on the cylinder has pins or has a shaft that the fibres can wrap around to prevent slipping. In this case the end cap winding is usually not part of the final product.

Advantages:

Can give greater choice of band pattern

Does not modify the wind angle on the rest of the path to achieve a band pattern

Can be useful on some difficult mandrels (see below)

Use of dwell winding on some difficult mandrels

In this example the winding angle on the cylinder is low and using geodesic winding the fibre passes onto the end shaft without turning as in the first picture.

To wind this part right hand friction is used to turn the path faster as shown in the second picture.

With non-geodesic winding on a flat-ended mandrel like this there a risk of fibre slippage often the part will wind ok at one speed but will slip if the winding is speeded up. The solution is to use dwell winding to add rotation to wind the fibre around the shaft as shown in the third picture.