Spar Winding -High Angle Parameters

Cadfil Help contents

Cadfil Help contents  Cadfil.com Home

Cadfil.com Home

The SPAR winding software is found on the QuickCAD main menu (if optionally supplied). This allows the winding of non-round sections of constant or near constant section. The section should not have concave portions, as these cannot be wound successfully.

High angle winding typically 40-90 degrees is where the end are not over-wound and there is a turning length at each end of the mandrel, then lngth of which is controlled by the friction parameter. Generally if the wind angle is less than 40 degrees the turning length (which may be scrap material) tend to become impracticably long. Note that for hoop winding it is quicker and simpler (and the programs are smaller) to use the Cadfil pipe winding option using the equivalent mandrel radius (spar perimeter/2PI) and ensuring the radial clearance is greater than the maximum radius of the section.

Click here to return to the main topic

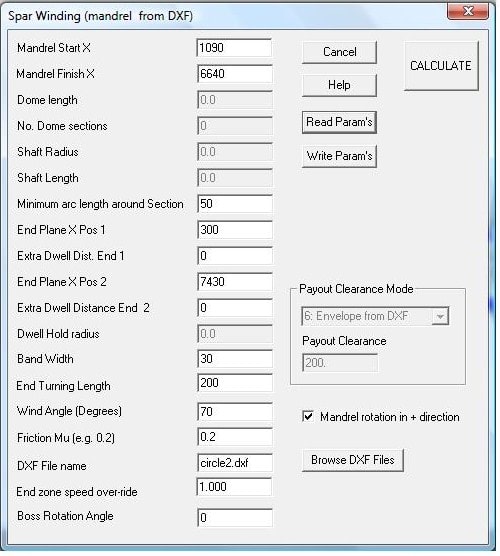

The windows dialog below is used:

Note that of the parameters may be greyed that is the user cannot select or enter data. This is because those options are not used and are retained for compatibility with different software options or for future options.

Mandrel Start X Start and Mandrel Finish X. These define the length (X finish- X start) of the winding program and where it is positioned relative to the mandrel origin (the x=0 position). The position of mandrel origin in the machine will depend on the machine datum's and the XDAT parameter described elsewhere in this help file under post-processing.

Minimum Arc length around the section, is the typical spacing of data points along the path on the mandrel surface, the units will be the same as the mandrel units usually mm or inch. For reasonably accurate winding about 8 points per rotation (for higher angles) is more than adequate, however when the user looks at the Cadfil graphics the path will appear not to be smooth. If good graphics are required use a small spacing. Please note that calculate time will be large and the data files and winding programs will be large if the spacing is small.

End Plane X position 1 & 2. These values are used for low angles winding to limit the travel of the mandrel carriage at the mandrel ends and to determine the smallest radial position the cross feed axis can move in to at the mandrel ends. Position one is at the X- end of the mandrel and position 2 is at the X+ end. If these items are greyed they are not required for the winding option chosen. WARNING the machine can move inwards and could clash with the mandrel if the planes are not positioned outside the extremes of the constant spar section.

Extra-Dwell 1 & 2 is a distance circumferentially around the mandrel at either end that the winding will dwell. This is a minimum value as additional dwell my be required for the purposes of making a proper winding pattern.

Bandwidth is the actual width of the fibre band to be used. This is used to calculate the number of carriage circuits required for a layer and is also used for the graphics of the banding structure.

End turning length is the distance (at both ends of the mandrel) than can be used to turn the fibre. The fibre starts at hoop and progresses down to the required winding angle. If the software can achieve the required wind angle in a shorter distance it will do so and the length of winding at the required angle will be correspondingly longer. If the length is less than that actually required a warning is given and the wind-angle that is achieved will not be the specified wind angle, the wind angle that is achieved is reported to the Cadfil text window.

Friction (coefficient) Mu is used to determine how quickly the fibre turns, a high value makes it turn faster and visa-versa. A value of about 0.2 is good for most purposes. If winding with pins on the mandrel near the ends use a very high value to turn the path quickly just outside the row of pins. Please not, Cadfil cannot defy the laws of physics, wishing for a high friction value to turn a path quickly will not make the impossible possible.

Wind angles (Degrees) , is the value in degrees that the user requires in the central portion of the wind path i.e. the total length excluding and turning zones. The Low angle option does not have a turning zone as the fibre turns on the mandrel ends thus the wind angle is fully upto the mandrel end.

Payout clearance and mode. This feature is no longer used as the clearance is always from the DXF file as this is the most general and flexible method.

Mandrel Direction check box. If ticked (default) the program is generated such that the mandrel rotates in the positive direction.

End-Zone Speed Over-ride. This options is not currently used. The function is to apply a factor to the winding speed in the turning zone.

Boss Rotation Angle. This option is not currently used.