Spar Winding (Prismatic non-round sections)

Cadfil Help contents

Cadfil Help contents  Cadfil.com Home

Cadfil.com Home

The SPAR winding software is found on the QuickCAD main menu (if optionally supplied). This allows the winding of non-round sections of constant or near constant section. The section should not have concave portions, as these cannot be wound successfully.

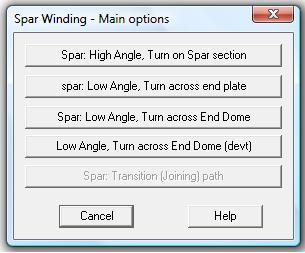

There are a number of options accessed from the menu dialog shown below

High angle winding typically 40-90 degrees is where the mandrel ends are not over-wound and there is a turning length at each end of the mandrel, the length of which is controlled by the friction parameter. Generally if the wind angle is less than 40 degrees the turning length (which may be scrap material) tend to become impracticably long. Note that for hoop winding it is quicker and simpler (and the programs are smaller) to use the Cadfil pipe winding option using the equivalent mandrel radius (spar perimeter/2PI) and ensuring the radial clearance is greater than the maximum radius of the section.

Low angle winding where the winding paths pass over the mandrel end, this is generally required for wind angles less than about 40 degrees (0 degrees being axial). The software automatically generates the mandrel geometry. There are three variants:

The mandrel has a flat end plate with a pin ring

The Mandrel has a idealised ellipsoidal end-dome (Spar Low angle Turn across end dome)

The Mandrel has a idealised ellipsoidal end-dome with an elliptical end boss and an enhanced clearance surface (Low Angle, Turn across end Dome (devt))

Transition (joining) paths generate a single path program to be created to go from programs of different wind angle and/or start position.

This function is not available at the present time

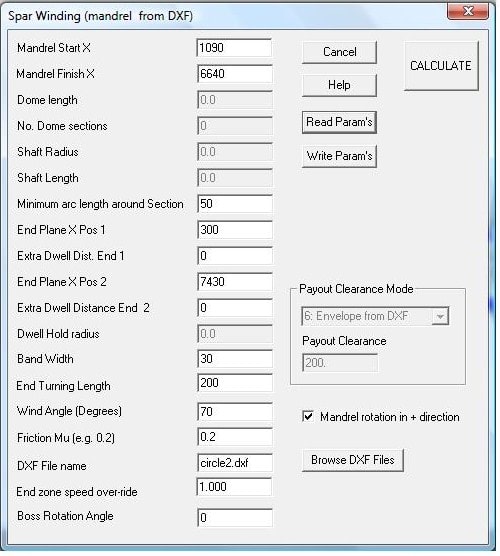

For all of the options a windows dialog like the one below is used, the parameters and descriptions vary for each option. The common features are described here and further details are given under the links for the specific options.

There are five button options:

CANCEL to quit without saving.

HELP to jump into this help file

READ PARAMS to read a set of data parameters created at an earlier time and that were saved to a .PAR data file.

WRITE PARAMS to write the current data parameters on the screen to a .PAR data file.

BROWSE DXF FILES to select from existing DXF files and add the DXF name to the winding data parameters. The DXF file contains the mandrel section and clearance geometry. Rules for creating this geometry are given by following this link.

CALCULATE to save the existing winding parameters on the screen and if possible calculate the winding pattern using them, some useful information messages are given to the Cadfil text window, read them!